Emily Piner presented with success and great interest from the audience her work, titled “A Biobased Alternative for Aseptic Packaging” at the 25th ACS Green Chemistry and Engineering Conference.

ABSTRACT

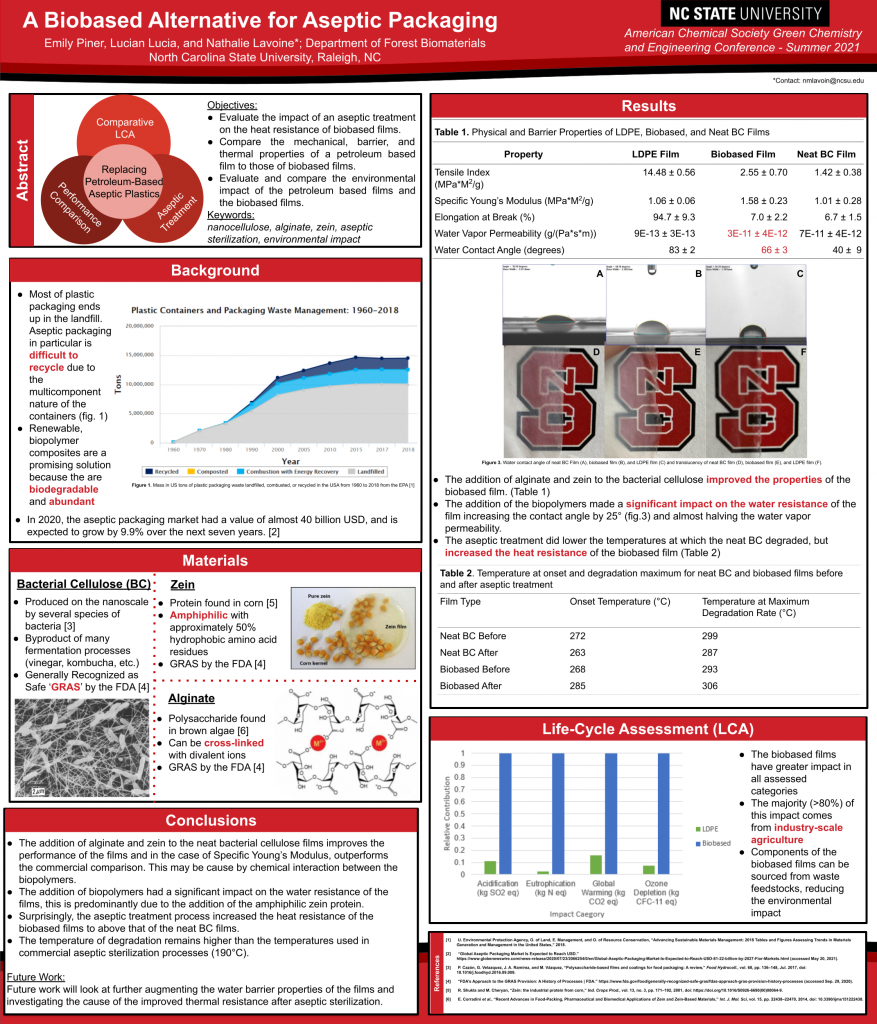

In 2020, the aseptic packaging market was valued at just under 50 billion USD, and is expected to grow at a rate of 6.65% over the next five years. This packaging is typically made of non-easily recyclable multilayers, made of petroleum-based plastics like polyethylene, polypropylene, and polyethylene terephthalate, and then exposed to harsh sterilization processes to sanitize the material before use in e.g., food, or medical packaging. However, with the ongoing threat of global climate change and the crisis precipitated by plastic waste pollution, there is a push from consumers to move toward more sustainable solutions.

The goal of this project is twofold: (i) evaluate the environmental impact and measure the physicochemical properties of commercially-available, petroleum-based, aseptic films, and (ii) propose a sustainable alternative derived from biopolymers that can match or outperform petroleum-based films.

To accomplish these goals, a series of commercial aseptic packaging films were purchased and their properties (tensile strength, gas and liquid permeability, thermal resistance, and transparency) were evaluated and compared. For the sustainable alternative, three biopolymers were selected based on their intrinsic properties and composite films were produced at lab-scale by solvent evaporation. Once a suitable film was developed, it was submerged in hydrogen peroxide and dried at high heat, emulating a widely used aseptic sterilization process, and its physicochemical properties evaluated and compared to those of the commercially available films. Reproducibility of all data was determined with an ANOVA test.

Environmental impact studies and life-cycle assessments of both the commercial and lab-made specimens were developed and compared. As a result of this work, a sustainable pathway toward aseptic packaging was proposed. Future research will consider the impact of these modifications on the biodegradability of the films, and possible further modifications for enhanced performance to achieve similar or better properties than commercial products.

Interested to know more about it? Please contact her at emvaller@ncsu.edu.