Resources

PAL Research Group has access to state-of-the-art facilities (bench- and pilot- scale) to conduct cutting edge research in sustainable and functional bioproducts to deliver top-class hygiene, smart packaging, and flexible electronics/3D materials and products that benefit society as well as the environment.

About

- Extremely diverse team of engineers, chemists, scientists and economists

- Highly trained professional faculty, staff, graduate research assistants (Ph.D. and M.S. Students), and undergraduate researchers

- Strong funding support from industry, NGO’s and public agencies

A short list of relevant equipment located in the faculty laboratories is provided below:

- High shear mechanical devices for nanomaterials production

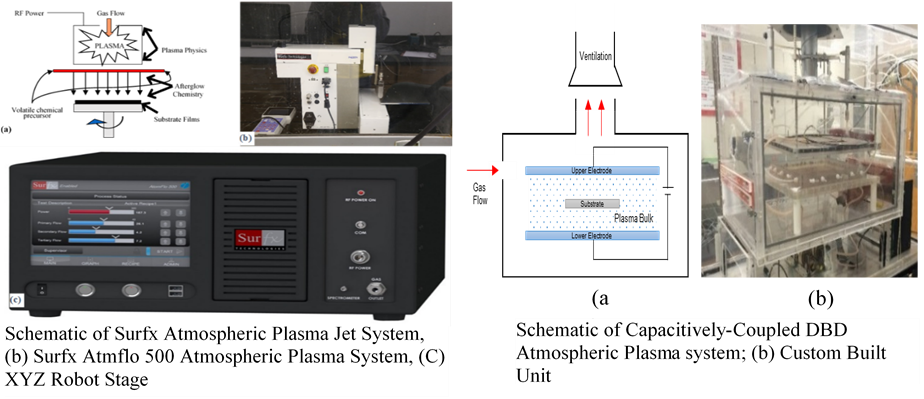

- Two atmospheric plasma units

- Mocon-OX-TRAN-Oxygen-Transmission-Rate-Tester

- Mocon-PERMATRAN-WVTR-Tester

- Electrospinning unit

- 3D material deposition printers

- Image analysis (microscopic and scanner)

- 3D scanning system

- QD proofer coating with gravure and flexo coating and printing heads

- Euclid blade coater

- Rod drawdown system

- Roll-to-roll coating machine with roll applicator and air-knife metering

- Hot air, IR and UV curing units

- Hercules Hi-Shear viscometer (HHSV)

- Brookfield viscometer

- Advanced rheometer

- Melt-flow indexer

- Injection mold

- Mini-Haake Micro-Compounder

- fully-equipped mechanical, optical and surface properties lab

- KRÜSS spinning drop tensiometer

- Contact angle goniometer

- Charge demand analyzer

- Horiba laser scattering particle sizer

- Malvern zetasizer nano

- Confocal and polarized microscopes

- X-Supereme 8000 ED-XRF spectrometer

- Coating mixers and various applicators

- Aging/yellowing via controlled irradiation, and various environmental chambers, etc.

- In addition, advanced analytical tools such as DSC, TGA, FTIR, NMR, AFM, SEM, ToF-SIM, HPLC, GC/MS, etc. accessible in various central laboratories on NCSU campus.

The paper, coating and recyclability testing and development is supported by the department’s pilot plant facilities. Our pilot facilities include a wide range of pulping, bleaching, papermaking, and separation technologies from chipping to the finished sheet. Our pilot plant includes a Fourdrinier paper machine, which has a 12-inch deckle width and a speed of up to 150 feet per minute. The machine is equipped with a wet-end shake, size press and calender stack. The pilot machine is used for research, as well as for training and contract trials.

Recently added equipment: