Teaching

Dr. Pal's teaching method is "DRIVE"

Deliver challenging, interesting and useful bodies of knowledge.

Remove roadblocks by providing tools, training and mentorship.

Incorporate innovation for students to compete globally.

Value self-learning, critical thinking and diversity.

Engage, motivate and collaborate to create a fun learning experience.

Dr. Pal considers himself a facilitator of learning and looks forward to working with students to help develop essential skills for great success in their future jobs.

Dr. Pal admires Thomas Edison’s personality traits as an inventor and innovator. His favorite book is “Innovate Like Edison” by Michael Gelb and Sarah Miller Caldicott.

COURSES

- PSE 472 Paper Process Analysis

Course contents: This is a capstone experience course, allowing senior students to demonstrate their abilities in addressing practical real world challenges. They will use use the skills and knowledge that draws from the culmination of undergraduate work and serves as the final product of their degree. This course focuses on papermaking processes on pilot-scale equipment, and requires students to develop teamwork and communication skills, apply fundamental materials and process knowledge, and develop competency in gathering, analyzing, and reporting on data.

Learning outcomes: At the end of the course students will be able to measure, analyze, and evaluate the water and fiber balances around the wet end, mass and energy balances around the drier section of the pilot machine; analyze components and properties of commercial papers to determine the materials used and processing techniques employed; intelligently articulate the salient characteristics of various grades of paper; utilize critical thinking skills to design a furnish that will closely duplicate an existing product; design and produce a specific grade of paper, measure and evaluate its properties to determine if it meets specifications, and recommend actions to correct deficiencies; and formulate, apply, and evaluate paper coatings and print attributes.

Importance: I believe this course not only provides our graduating seniors fundamental papermaking process knowledge, but also provides them with hands-on learning experience, teamwork and communication skills, so that they can become effective engineers and leaders in the paper, chemical, and related industries.

- PSE 465 Advanced Process Engineering

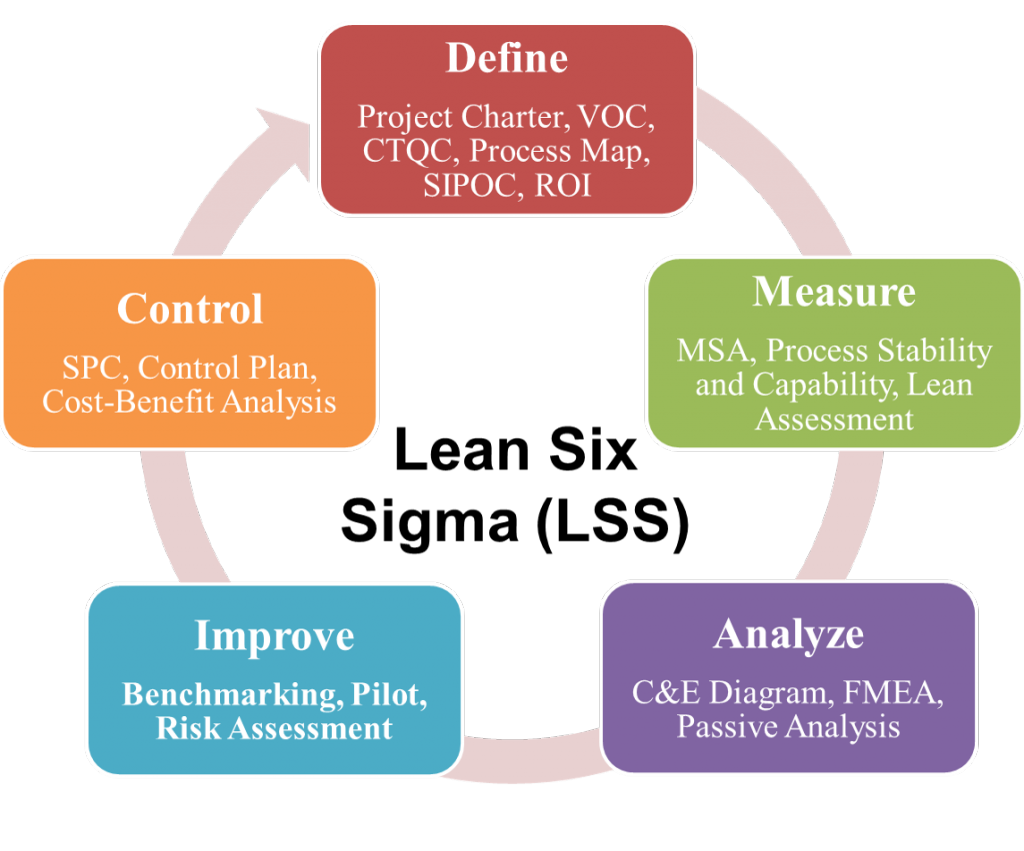

Course Contents: This course is designed to introduce our seniors entering the pulp and paper industry to advanced tools and techniques used by process engineers in process design, improvement, and operation. Topics include basic statistics, Lean Six Sigma/DMAIC methodology, statistical software, measurement system analysis, process mapping/value stream mapping, statistical process and quality control, control charts, process capability analysis, hypothesis testing, design of experiments, modeling, and big data analysis. An independent project is required, which can lead to LSS Green/Yellow Belt trained status.

Learning outcomes: At the end of the course students will know DMAIC methodology- Define (describe a problem), Measure (collect relevant baseline data), Analyze (identify the root causes), Improve (select the best solution), and Control (sustain the improvements). They will learn to use statistical software for data analysis.

Importance: This course provides a broader spectrum of learning and tools to extend our students’ marketability beyond the pulp and paper industry. Furthermore, the critical thinking and process improvement skills learned in this course are not only applicable to solve a variety of engineering problems in the workplace, but can also be used to improve the daily lives of participants.