Smart Manufacturing

Paper Pilot Plant Smart Manufacturing Innovation Center (P3-SMIC)- Building Powerful Research and Educational Platform in Partnership with the CESMII and Industry to Promote Immersive Learning

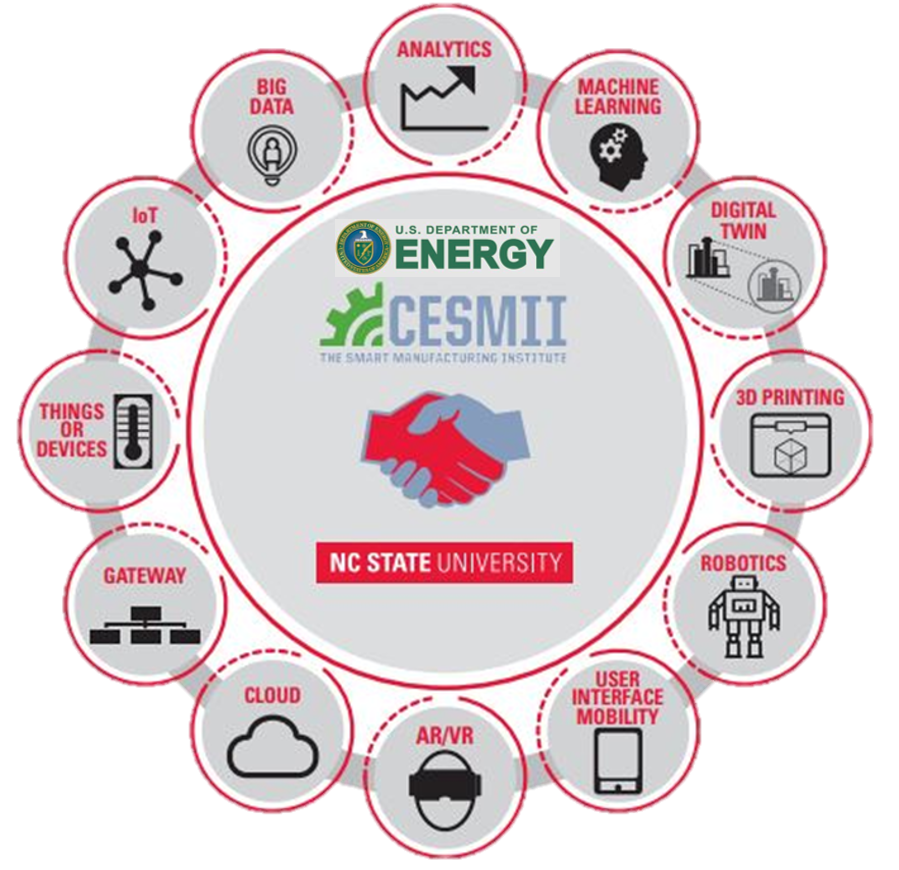

NC State’s Paper Pilot Plant Smart Manufacturing Innovation Center (P3-SMIC) core mission is the demonstration of the Smart Manufacturing (SM) Platform™ and development of the SM infrastructure for next generation of workforce training and research in strong partnership with the CESMII (Clean Energy Smart Manufacturing Innovation Institute) and industrial partners. NC State’s SMIC comprises facilities across campus from forest biomaterials, biomanufacturing, nonwovens textiles, and industrial system engineering.

P3-SMIC Core Mission:

- Smart Manufacturing (SM) Platform

Demonstration and Infrastructure Development- Access to CESMII’s SM Platform supported by the world’s leading technology companies

- Democratize data to unleash the collaborations though Open Knowledge Networks (OKN)

- Next Generation of Workforce Training Tools Development

- Develop curriculum focused on SM technologies, advanced process controls, machine learning, and artificial intelligence

- Offer industrial workshops in partnership with CESMII and SM Certificates

- Industry Ecosystem Development

- Collaborate with industry stakeholders to facilitate large scale SM adoption

- Mitigating risks and barriers to adoption through technology demo and training utilizing our P3-SMIC facility

The US Forest Products Industry anticipates a rapid ascent in solid wood products, high-purity cellulose fibers, dissolving pulps, tissue and hygiene, and packaging. Materials breakthroughs in highly functional nanomaterials and tree improvement biotechnologies are keys for next generations of sustainable and smart products like lightweight automobile parts[i] and customizable buildings.[ii], [iii], [iv], [v] To achieve those ends, the industry aims to generate one billion tons/yr of biomass products by 2030 without disrupting food/feed markets or having negative environmental impacts.[vi]

SM technologies can streamline complex manufacturing by allowing devices, sensors, and controls to share information for highly efficient manufacturing.[vii] A concerted integration of SM in biobased economy will give the US a competitive edge in the global economy by delivering smart multi-dimensional, low cost, sustainable, and renewable materials.

The strong partnership with CESMII and industrial partners will lead to a world-class P3-SMIC for bioproducts innovation and a multi-disciplinary educational ecosystem for planned smart workforce development, enhancing forest products industry competitiveness internationally.

Facilities

Stock Preparation and Refining

Stock preparation can process many different types of raw materials (such as wood, non-wood, agriculture wastes, marine wastes, recycle fibers) with industrial-scale units such as hydrapulper, screen, cleaner, washer, thickener, and refiner. Chemical Additives

Chemical additives system allows the addition and study of various chemistries simultaneously to understand the interaction in a papermaking environment. The chemicals can be added in hydrapulper, mixing tanks (before refiner) or machine chests (after refining), before or after fan pump, headbox, wire, presses and dryers. Papermaking

The pilot paper machine is available for material and process studies such as small-scale paper making using various fibers, additives, and coating. This includes the use of paper pilot machine to evaluate equipment components.

- Fourdrinier paper machine

- Basis weight range – 20 to 400 gsm

- 20 to 150 fpm

- 12” trim width

- Automated wet-end additives for multiple additives.

- Two felted press nips

- Smoothing press

- Inline size press

- Steam jacketed starch and other biopolymers cooking system

- In-line steel nip calendar stack

- High precision drive system

- On-line monitoring of tank level, thick stock and headbox flow, consistencies, conductivity, pH, steam pressure, temperatures, basis weight, and moisture,

Inline Size Press

Size press allows the application of various surface treatments such as starches and other biopolymers as well as synthetic additives to expand the substrate functionalities such as look and feel, barrier (moisture, gas, oil and grease), and printing properties. Inline Calendering

An online calender stack is available at the end of the paper machine to enhance the functionalities of the substrates such as smoothness, porosity, gloss, etc. We also have an off-line calender (conventional or hot soft nip configuration). Offline Coating

For adding functionality and value to the products, a small roll-to-roll coating machine with roll, airknife, gravure, and flexo metering processes is available for coating and surface treatments on various substrates such as paper, film, foil, or composites. For example, we have conducted coatings for products such as digital printing papers, food packaging, and hygiene composites. The coating machine can process up to 9 inches width rolls at speeds of up to 130 fpm. Digital Printing

A wide variety of bench-top printers for inkjet, electrophotography, flexo, and gravure printing are available for testing and research. We can perform a number of different printing tests such as density, gloss, dot gain, mottle, image and text analysis, wet and dry durability, smudge, dry time, etc. Sensors and Data Capturing

A wide variety of field sensors mounted on the paper machine, acquiring data via NI LabView with an OSI PI connection for data storage and retrieval. Paper Pilot Plant: Continuous Process Monitoring

Resources available includes:

- Process and product testing, for example

- Evaluate raw materials, mechanical treatments, and chemical additives

- Evaluate equipment performance – new equipment design and processes, sensors

- Evaluate surface treatments and coatings- starches, nanocelluloses

- Evaluate mechanical, surface, optical, structural, barrier, printability, biodegradation performance

- Innovate sustainable barrier coating and nanocellulose-based functional materials development

- Evaluate new materials, formulations and processes

- Workforce training and tools, for example

- Hands-on industrial short courses

- SM platform and tools demonstrate workshops

- Advanced process engineering, lean six sigma, and statistical analysis workshops

- Data analysis and predictive modeling

- Digitization/machine learnings

[i] http://www.autocar.co.uk/car-news/new-cars/honda-reveals-3d-printed-electric-car

[ii] Global Construction Outlook 2030, https://policy.ciob.org/wp-content/uploads/2016/06/GlobalConstruction2030_ExecutiveSummary_CIOB.pdf

[iii] Pal, L., Joyce, M. (2017), Paper need not be flat: Paper and biomaterials industries need to converge to bring about true innovation. BioRes. 12(2), 2249-2251.

[iv] http://inhabitat.com/dubai-debuts-worlds-first-fully-3d-printed-building/

[v] https://newatlas.com/marine-corps-systems-command-3d-printing-barracks/56261/

[vi] Jobs and Economic Impact of a Billion-Ton Bioeconomy, US Department of Energy, DOE/EE-1560, June 2017, https://www.energy.gov/sites/prod/files/2017/06/f35/jobs_and_economic_impact_of_a_billion_ton_bioeconomy.pdf

[vii] Smart Manufacturing: Transforming America Manufacturing with Information Technology, Office of Energy Efficiency and Renewable Energy, DOE, June 30, 2016, https://www.energy.gov/eere/amo/articles/smart-manufacturing-transforming-american-manufacturing-information-technolog